Injection molding for the highest demands

Our injection molding serves a wide range of essential applications in the automotive industry, medical technology, mechanical engineering, and electrical engineering. With our plastic injection molding and tools, we deliver precise and cost-effective solutions.

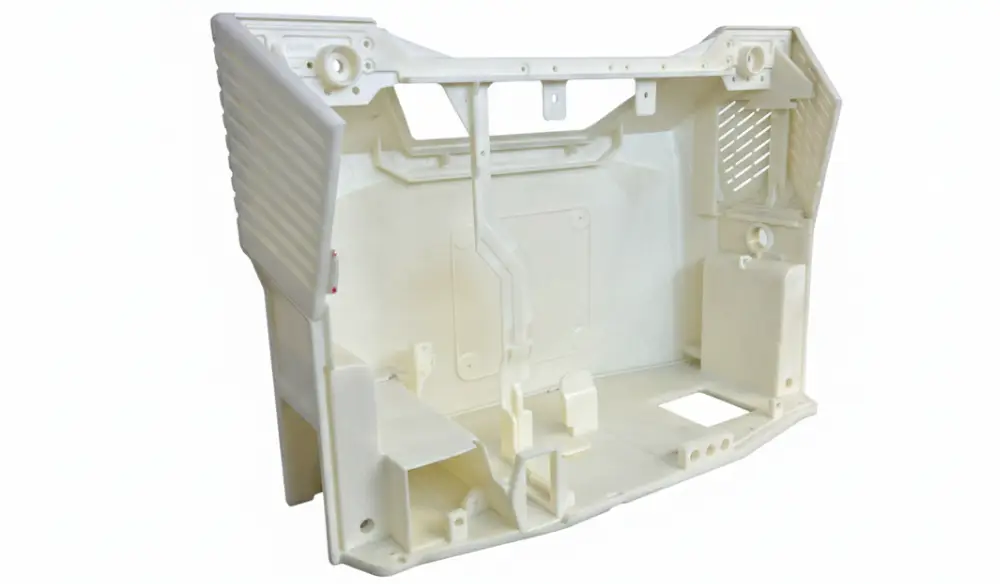

Injection molding of plastic components – quality and efficiency

Producing plastic parts through injection molding demands utmost accuracy and dependable processes. Our advanced machinery, featuring over 27 energy-efficient injection molding machines with clamping forces from 35 to 1,600 tons, allows us to create plastic parts weighing between 1 and 4,500 g with consistent quality.

With years of experience and cutting-edge technologies, we craft solutions tailored to your exact needs. Our expertise spans from simple components to complex injection molding projects. We work with high-performance plastics like PEEK, PMMA, and TPE to meet demanding applications.

1K and 2K injection molding

Single-component technology (clamping force 35 to 1600 t) and two-component technology (clamping force 200 to 1120 t) for a wide range of applications

TSG thermoforming

Lightweight solutions with reduced material consumption.

Processing of high-performance plastics

Materials such as PEEK, PMMA and TPE for advanced applications.

Relying on our injection molding expertise, we design precise tools that guarantee the accurate production of your components.

Our injection molding solutions in detail

Precision

We produce injection-molded parts ranging from 1 to 4,500 g

2K injection molding for integrated functions

Create components with multiple materials in a single step

Thermoset foam molding (TSG)

Perfect for lightweight, high-strength components with optimized material consumption

Processing of high-performance plastics such as PEEK, PMMA, and TPE for applications in extreme environments

Overmolding and insert molding

Quality assurance

Request an offer

Precision in series production. Quality in every shot

As an injection molding company, we deliver reliability and cost-efficiency. If you need a service provider with both expertise and the flexibility to meet your specific requirements, we are your perfect partner.

Using state-of-the-art machinery and a broad range of injection molding techniques, we produce plastic parts for every application — from intricate precision components to large, complex structures. We work with a wide variety of plastics, including high-performance materials like PEEK and PMMA, while prioritizing resource-efficient and energy-saving production.

„Our solutions fit your needs. If you are seeking for an versatile injection molding toolmaker, you have come to the right place. Our state-of-the-art machine park features over 27 energy-efficient injection molding machines from top manufacturers, with clamping forces spanning 35 to 1,600 tons. They deliver power, reliability, and sustainability.“

We are here for you

Do you need customized injection molding solutions? We’re here to help!