Plastic parts for mechanical engineering, medical technology, and other industries

For decades, we have supplied mechanical engineering, medical technology, and other demanding sectors, including electrical engineering, the chemical industry, and lightweight construction in mechanical engineering.

Reliable supplier of plastic parts

We design and manufacture premium plastic parts, components, and tools through advanced injection molding. With modern manufacturing technology and deep material expertise, we ensure precision, durability, and dependable processes.

Our customers come from industries such as:

Mechanical and plant engineering

Medical technology

Chemistry

Electrical engineering

Plastic parts for peak industrial performance

Our customers — whether in mechanical engineering, medical technology, or lightweight design — trust our flexibility, precision, and reliability, even for small to medium production series.

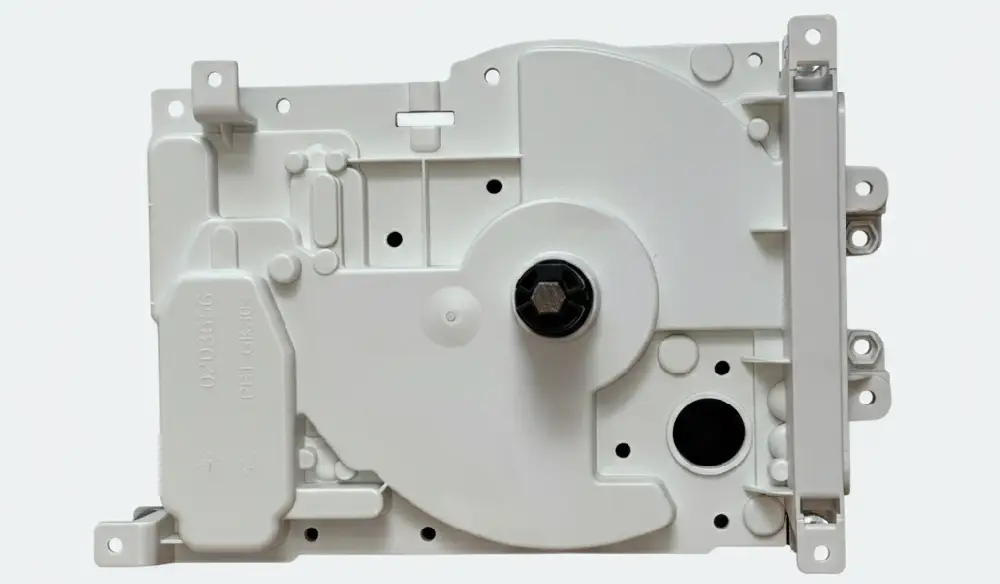

Mechanical engineering: Robust, precise, and durable solutions

For mechanical engineering and plant construction, we manufacture:

Precise plastic components for mechanical engineering

Wear-resistant functional components

Complex geometric components

Components using modern plastic injection molding processes

Perfect for small and medium series production and custom-made designs.

Superior quality and reliable processes

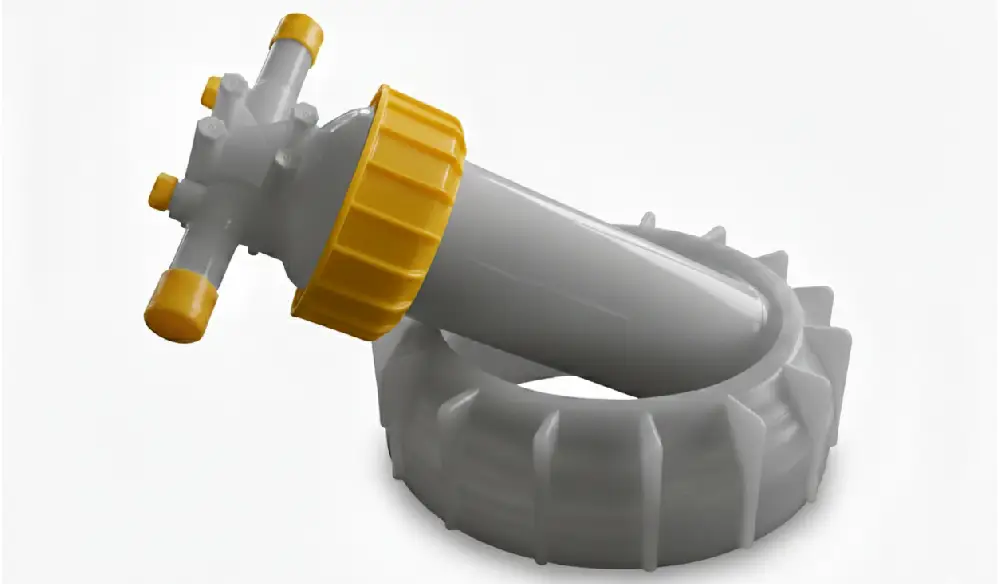

We provide plastic components and assemblies for:

Technical components in medical devices

High-precision functional components

High-voltage shielding components for electrical engineering

Water filtration systems

Defense solutions

We manufacture in accordance with ISO standards and strict quality guidelines.

Lightweight design is gaining importance in industrial settings.

- Designing thin-walled structures

- Selecting optimized materials

- Integrating multiple functions

- Developing durable, weight-reduced components

Our expertise at a glance

-

Designing reliable tools

-

Producing series in line with ISO 9001 standards

-

Delivering automotive injection molding for small, medium, and large series

-

Operating 27 energy-efficient injection molding machines

-

Crafting automotive plastic parts and intricate assemblies

-

Excelling in automotive assembly and component production

Your benefit as a customer

Precise and reliable processes

Quick product changes and minimal setup times

Energy-efficient production

Low waste rates

Flexibility for small to medium series

Direct representatives and swift decisions

“We embrace new challenges without hesitation. Each industry has unique needs — and we provide solutions that deliver results.”