Precision drives excellence in tool and mold making

For over 60 years, we have harnessed cutting-edge technology to craft tailored solutions in tool and mold making that meet your production needs. We create injection molds for both small and large series, focusing on plastic components and assemblies.

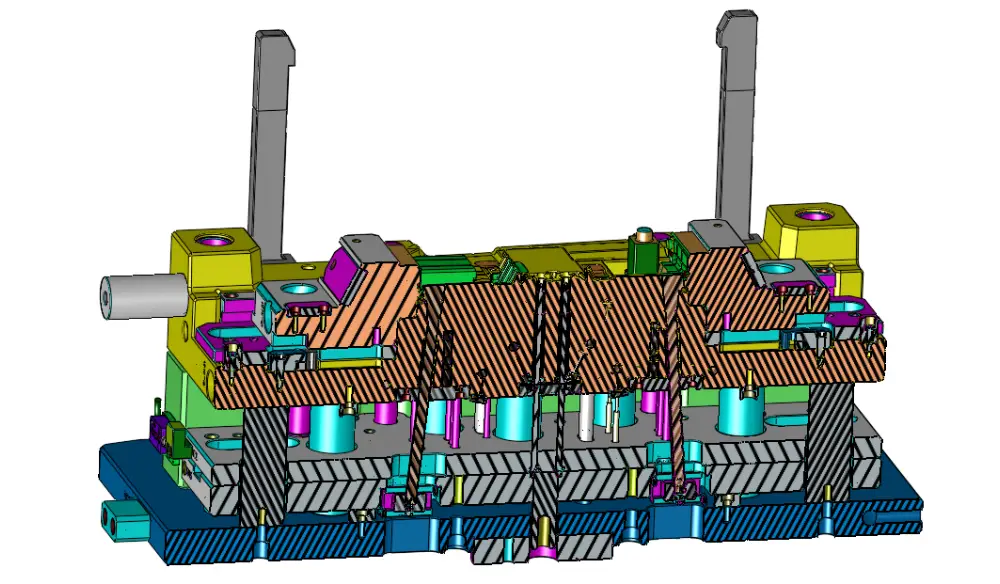

Toolmaking that sets standards

We design and produce tools for industrial manufacturing that fulfill your quality management and assurance needs while streamlining your production processes for efficiency and cost savings. Our expertise includes crafting injection molding tools from aluminum and steel, creating custom tools, and delivering precise solutions for plastic mold production.

Selected services in detail:

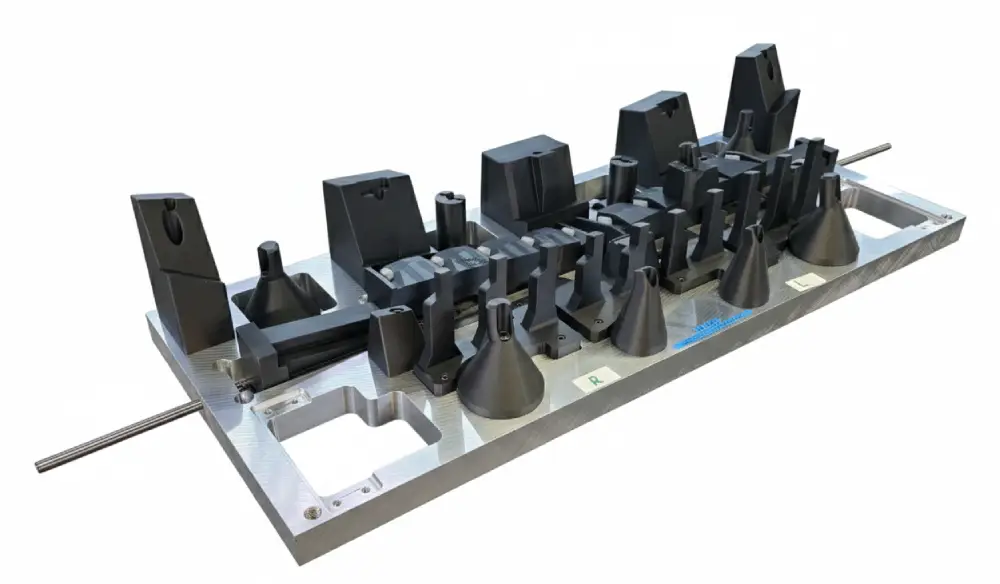

Aluminum and steel tools

We provide customized solutions for pilot, small, and large series production. These tools suit both complex and simple applications, including component manufacturing

Special tools for complex parts

Whether you need hot runner tools, cascade tools, or 2-component tools, we deliver solutions precisely tailored to your industrial manufacturing needs

Tool maintenance and optimization

Our regular maintenance services extend your tools’ lifespan and ensure they meet ISO 9001 quality management standards

Our expertise in tool and mold making

Our skilled team leverages cutting-edge technologies to optimize your production processes:

Custom tools for complex demands

Durable tools for lasting performance

Built for longevity, our tools lower your production costs while maintaining consistent product quality.

Tool maintenance and repair

Regular maintenance and swift repairs keep your tools running efficiently and minimizing downtime

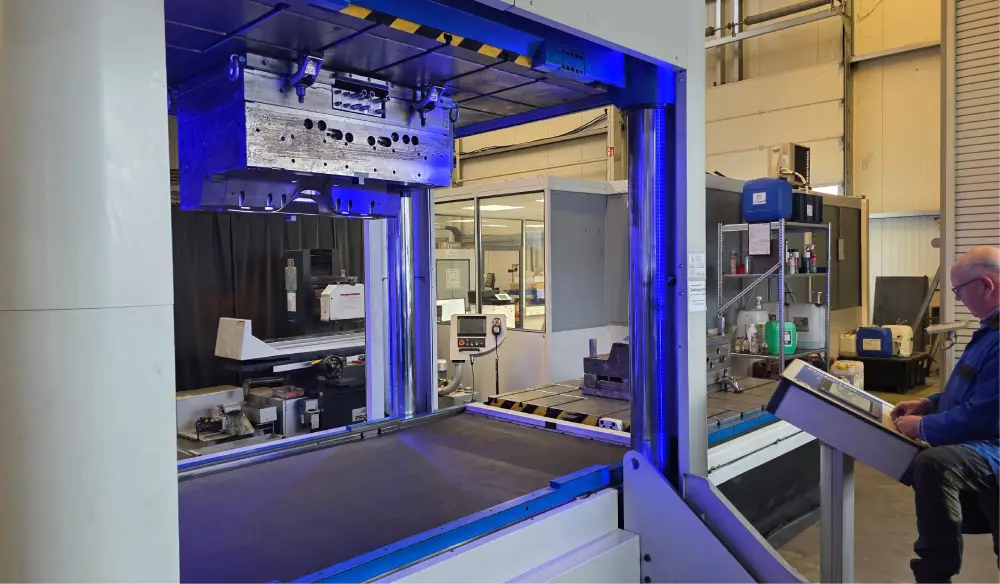

Advanced manufacturing technologies

Using rapid prototyping, 3D printing, and innovative materials, we deliver solutions precisely tailored to your requirements

Tooling for the Future

Modern injection molding tools must meet the strictest standards in quality assurance and quality management. Through our tool and mold making, we ensure unmatched precision, reliability, and innovation for our customers in industry and the automotive sector. We deliver first-class quality on schedule and at fair prices. To date, we have successfully produced over 3,500 tools for industrial production.

„A great tool is never a matter of chance. Our tool and mold making is driven by experience, precision, and passion.“